One of the most popular systems on the market and the one i have the most experience working with is the dynavibe gx3 system from rpx technologies.

Dynamic propeller balancing equipment.

Have been working for more than 25 years to provide industry leading aviation vibration analysis and portable vibration balancing equipment to the fixed wing and helicopter aviation industry.

Dynamic propeller balancing equipment features.

Dynamic propeller balance aviation track and balance equipment.

Report generation graphical setup.

Buy now vibration magnitude.

Dynamic propeller llc develops and distributes innovative products for cessna aircraft.

The affordable dynamic prop balancer the dynavibe classic is an economical state of the art dynamic propeller balancer designed specifically for the aircraft industry.

The dynavibe classic displays the magnitude and phase of propeller vibration allowing precise weight adjustments for balanced and smooth engine operation.

Affordable dynamic propeller balancing equipment customers call it stunning and remarkable dynavibe classic our simplest easiest to use and most affordable vibration solution.

Graphically configure the dynavibe gx to match your aircraft.

Commercial aviation serving the commercial airline transportation cargo industry.

Fixing dynamic propeller balance is a vital factor in maintaining an airplane s service life.

Strict guidelines determine tolerances for optimal performance and safe operation.

Number of propeller blades number of potential weight adjustment locations and sensor configuration.

We offer dynamic propeller balancing as well as cessna carburetor heat box repair.

Located in the south eastern corner of washington state we specialize in products that address areas of high wear due to engine propeller vibration.

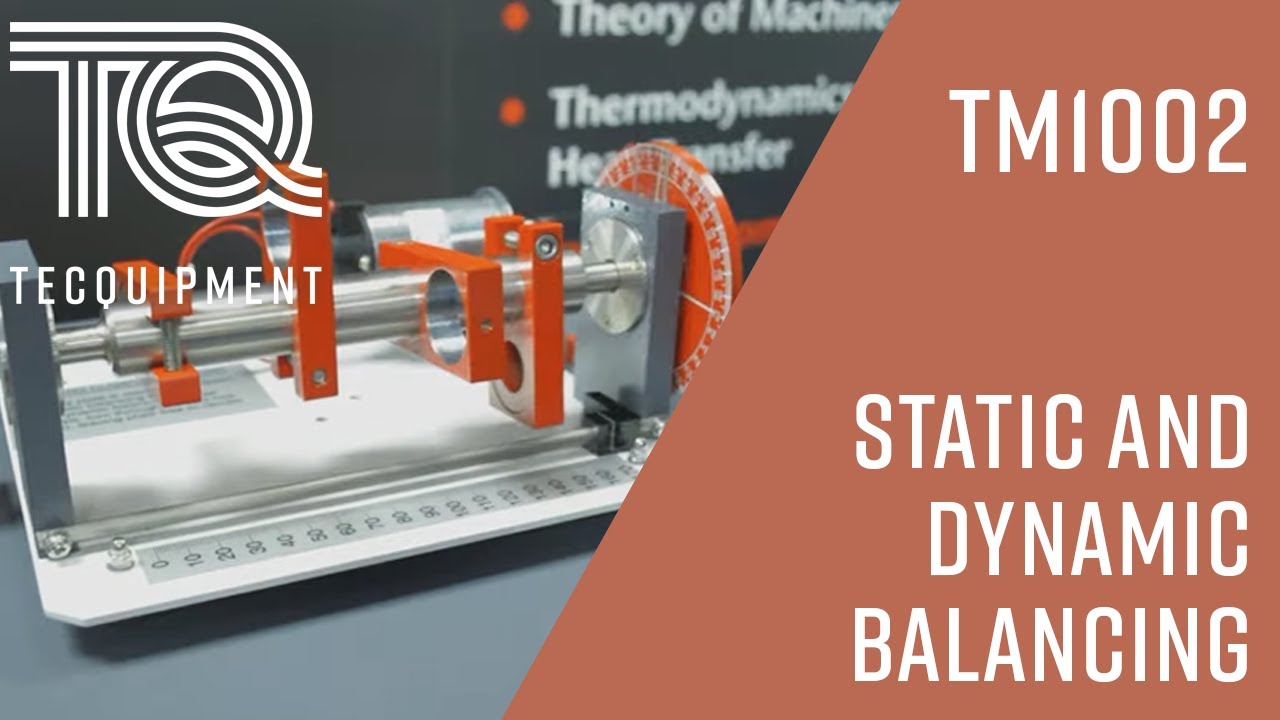

The typical dynamic balancing system consists of a vibration sensor that is attached to the engine close to the propeller and an analyzer unit that calculates the weight and location of balancing weights.

Small trim balance weights are added to the propeller crankshaft assembly to correct for errors in mass distribution and to reduce power plant vibration due to mass imbalance to the lowest level.

Even with regular maintenance and attention to these limits the dynamic components for a propeller system can become imbalanced.

Several manufacturers make dynamic propeller balancing equipment and their equipment operation could differ.

Dynamic balancing is accomplished using specialized equipment that can accurately measure the vibration and most importantly pinpoint exactly where the imbalance exists.